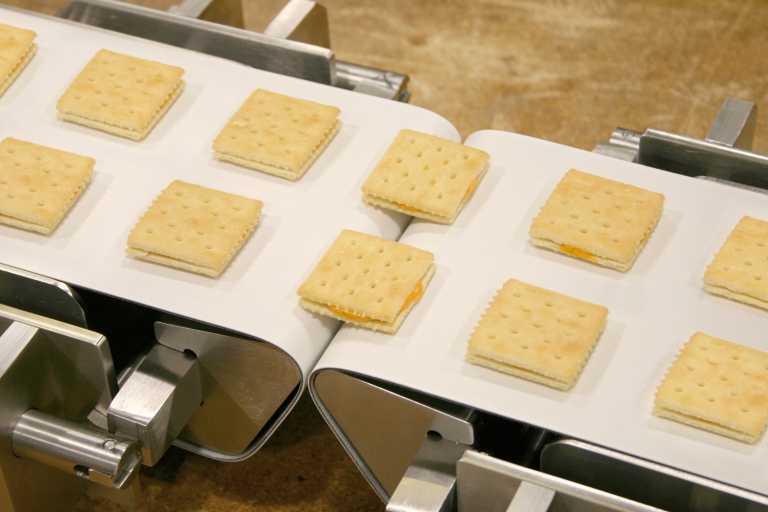

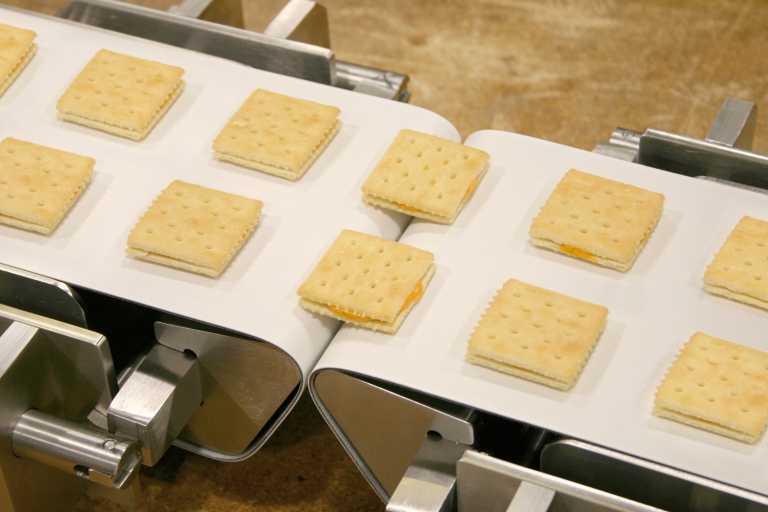

This week Manufacturing Food is reviewing global manufacturers of HACCP Conveyor Belts.

HACCP Food Conveyor Belts

Exactly what to search for in a sophisticated Conveyor Belt for the Food Industry that will certainly meet your processing demands.

- A conveyor belt must be made for quick and also reliable hygiene.

- Mainline conveying system or a hand packaging station

- Straight as well as curve sections are an in addition to in a food belt conveyor

- Tip up tails

- To have nose bar alternatives

Various food conveyor belts are needed for various reasons.

Deppends on your food application.

Polyurethane belting, for sharing food in direct contact with the belt, is also suitable for little size rollers and also bull noses, is conveniently cleaned up and difficult wearing. This belt is also readily available with antibacterial buildings to stop microbial growth on the belt.

PVC belting can be made use of for conveyor lines where the food has been wrapped and also packaged.

Cotton and felt covered belts are used for moving dough and also various other sticky products because of their superb launch residential properties. The belts could be supplied in various colors, to suit the application. : Inkjet machines and assessment lines.

All HACCP food conveyor systems can be provided with air travels for applications including moving items up steep slopes such as plastic parts, soap tablet computers as well as food active ingredients. A full array of tracking strips are held in stock which could be bonded to the bottom of our conveyor belts to aid in real running. Make sure you select a correct supplier to be the manufacturer of your food conveyor belt.

Note: not all HACCP food conveyor belt manufacturers are based on Europe. You can buy from a global provider that has manufacturing facilities on other areas of the world. Just make sure the conveyor system you're buying is HACCP verified.

Main Applications that need a Food Conveyor Belt

Fruits - Veggies - Meats - Chicken - Fish - Refreshments - Grains

A

Food Grade Conveyor Belt needs to have a hygienic and also sanitary design so it can be utilized in your product processing. If it goes through a sieving machine before product packaging, you need to prevent any contamination of your last item even.

Main Industries for Food Conveyor systems:.

- Dough processing.

- Confectionary Industry.

- Meat, Pultry and also Seafood.

- Dairy products Industry.

- Agriculture.

- Product packaging.

Cotton and really felt covered belts are utilized for moving other and also dough sticky items due to their superb launch commercial properties. The belts could be provided in various shades, to match the application. Wire belt conveyor - offers risk-free handling of products in extremes of temperature. The invulnerable nature of the belt enables minimized leak and minimized product loss. Belt Conveyors of this type need mindful style and substantial know-how in this area and the makers need to make a conveyor that tracks appropriately as well as gives long as well as reliable service.

Why HACCP Conveyor belts?

HACCP is component of European Union Policy.

The

Hazard Analysis and Critical Control Point system is globally accepted as the system of option for food safety and security management. It is a preventative strategy to food safety and security based upon the following seven concepts:

- identify any sort of risks that should be prevented gotten rid of or minimized

- identify the important control factors (CCPs) at the actions at which control is essential

- establish crucial limits at CCPs

- establish treatments to check the CCPs

- set up rehabilitative actions to be taken if a CCP is not in control

- develop procedures to validate whether the above procedures are functioning properly

- develop files as well as documents to demonstrate the reliable application of the above steps

One of the questions we obtain a lot more commonly, is exactly what in fact HACCP means, as well as why is it so crucial to buy equipment that is HACCP verified. HACCP is part of European Union Regulation. The HACCP technique supplies a methodical way of determining food security hazards as well as making certain that they are being managed day-in, day-out. Sellers and consumers require to take preventative measures, consisting of temperature controls as well as maintaining raw meat as well as prepared meat as well as various other ready to consume foods separate.

So by having an HACCP Food conveyor, you can rest assure that your conveyor belt will be accepted and your product can be exported to EU.